Prof. Dr Sebastian Weber / Mechanical Engineering

Photo: UniService Transfer

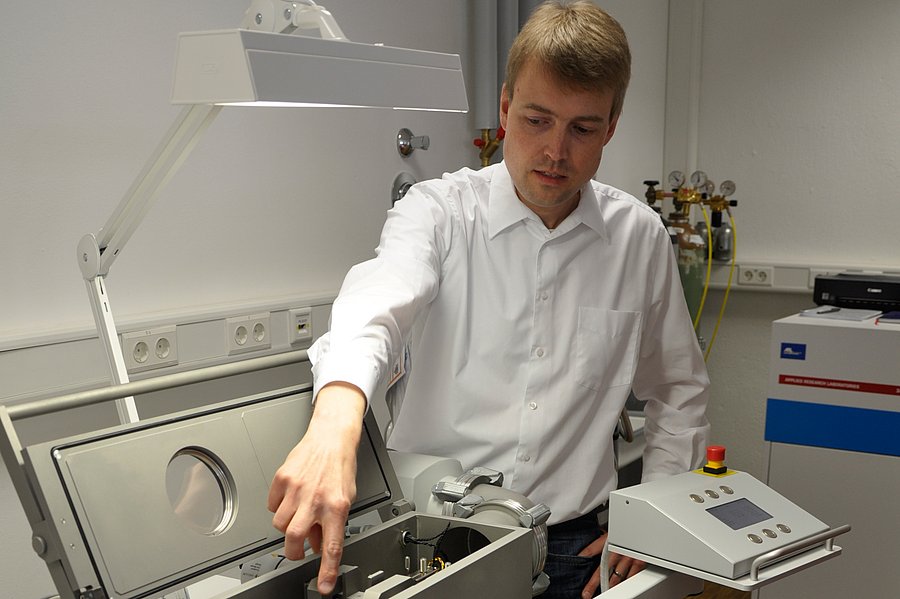

Dilatometer instead of steam engine

Endowed Professor Sebastian Weber and his Chair of New Manufacturing Technologies and Materials at the Product Design Forum in Solingen

The Product Design Forum at the University of Solingen is located in the newly remodelled former main railway station. Surrounded by shops, restaurants, sophisticated railway architecture and the Plagiarius Museum, it houses the Chair of New Manufacturing Technologies and Materials. The Science Transfer Office is hosted by the Chair's holder, Prof Dr Sebastian Weber, who took over the first endowed professorship** in Solingen in 2014.

As the host, he gives a tour of the remodelled rooms, is enthusiastic about the possibilities on site and says: "What we do here is presentable!" Seminar rooms in a sophisticated ambience are sometimes rented out to third parties and have already been included in the rectorate brochure "Central locations for special events". Offices and training rooms have been efficiently remodelled and laboratories, bright and flooded with light, create a pleasant working atmosphere.

Experience-based knowledge or research-based knowledge

The scientist, who specialises in materials made from metals, in particular iron, conducts basic research, carries out investigations into material-specific energy and resource efficiency and would like to anchor the sustainable development of heat treatment and forging processes more firmly in research and teaching. The breadth of his specialism, especially the path from application research to the end product, points to future strategies for companies in the Bergisch region. To this end, Weber seeks close contact with the city and industry and holds many discussions with regional players in order to build trust and break down prejudices, because, as he clearly states, "many companies have grown historically and have developed a wealth of experience. "For them," he continues, "it is initially incomprehensible why a recipe for success should be changed." However, the university can dock onto this with research-based knowledge. So it's not about competition at all, but about improvement through joint and interdisciplinary development. And the materials scientist has a lot to offer in this respect.

Dilatometer instead of steam engine

Take the dilatometer, for example. While our great-grandfathers were delighted with the development of the steam engine in the 19th century, today's mechanical engineers' eyes light up at the sight of the dilatometer. This highly sensitive device - which can also be found in the Bergische Universität's research database - calculates the volume from the change in length of a material following a defined heat treatment. Weber is well aware that the results on the usability of materials are of great value to the economy. For example, some new alloys are more cost-effective and therefore more economical than those previously used. However, energy and resource productivity is at least as important nowadays, especially in the case of metallic materials with their high primary energy requirements.

Weber also helps the Bergisch economy in the long term by retaining university graduates in the region. The most recent example of this is the first Master's graduate from his department, whom he himself supervised. In cooperation with Berghaus GmbH & Co KG, Lars Elbracht, who was born in Remscheid, graduated and was promptly offered a job in the design section. A real personnel transfer achievement!

Third mission projects

Weber has achieved a lot over the past three years as a competent contact person. He is well networked, has made a lot of contacts and is active in many important committees. He also has ideas on the subject of "Third Mission". He mentions his contribution to the "Innovative University" funding application, which, if approved, he would like to establish a science shop in his own building. The space is available, and the Product Design Forum could then be used to provide advice on research, studies and teaching, and to welcome interest groups and schools in order to better inform the public about university activities and establish contacts.

Equally exciting is a project launched by the city of Solingen with the agency Engagement Global gGmbH entitled "Globally Sustainable Municipality in NRW", on whose strategy group Weber sits on behalf of the university. Together with representatives of employees and employers, church representatives and people from the city administration, associations and schools, among others, they are all working together on this municipal third mission project.

The aim is to develop guidelines and objectives for a sustainability strategy; the focus is on a programme of action with measures and projects on topics such as climate and energy, mobility, business and work.

And what else?

Of course, the married father also looks outside the box. Co-operations with two Polish universities and with South America already exist, and a further collaboration with a West African country is being planned.

And the students? They should have an affinity for the subjects of maths, physics, chemistry and technology, because: "If prospective students have a good grasp of technical and scientific principles," he says, "they will find the best conditions at the University of Wuppertal." Professor Weber emphasises the good supervision ratio, i.e. the ratio of lecturers to students, the direct, very personal contact with the lecturers and the Master's cohort of around 40 people in mechanical engineering.

With his team of five academic staff, a secretary and a number of student and research assistants, his department is very well organised.

If he could wish for anything else, he would be delighted to have a metal 3D printer. Maybe then you could find it in the researcher database.

Uwe Blass (interview from 23/05/2017)

Prof Dr Sebastian Weber studied materials science in Darmstadt from 1997, specialising in "Electronic Material Properties" and "Physical Metallurgy" at the Technical University of Darmstadt. After graduating in 2002, he joined the Chair of Materials Engineering at the Ruhr University Bochum as a research assistant. He completed his doctorate there in 2005, followed by scientific positions at the Max Planck Institute for Iron Research (MPIE) and the Helmholtz Centre Berlin (HZB). In 2009, Dr Weber received the Thyssen-Krupp Materials Innovation Award for his work on "Sintercladding - Development of a new process for the production of highly wear-resistant coatings". After completing his habilitation at the Ruhr University Bochum, he took up the endowed professorship in the Chair of New Manufacturing Technologies and Materials at the University of Wuppertal, based at the Forum Produktdesign in Solingen.

(**13 companies from the district of the Wuppertal-Solingen-Remscheid Chamber of Industry and Commerce (IHK), together with the Stifterverband and Sparkasse Solingen, have raised over 1.6 million euros in funding to establish a mechanical engineering endowed professorship at the University of Wuppertal, based in Solingen, over a period of five years).