Research project

Automated quality inspection of printed circuit boards with artificial intelligence

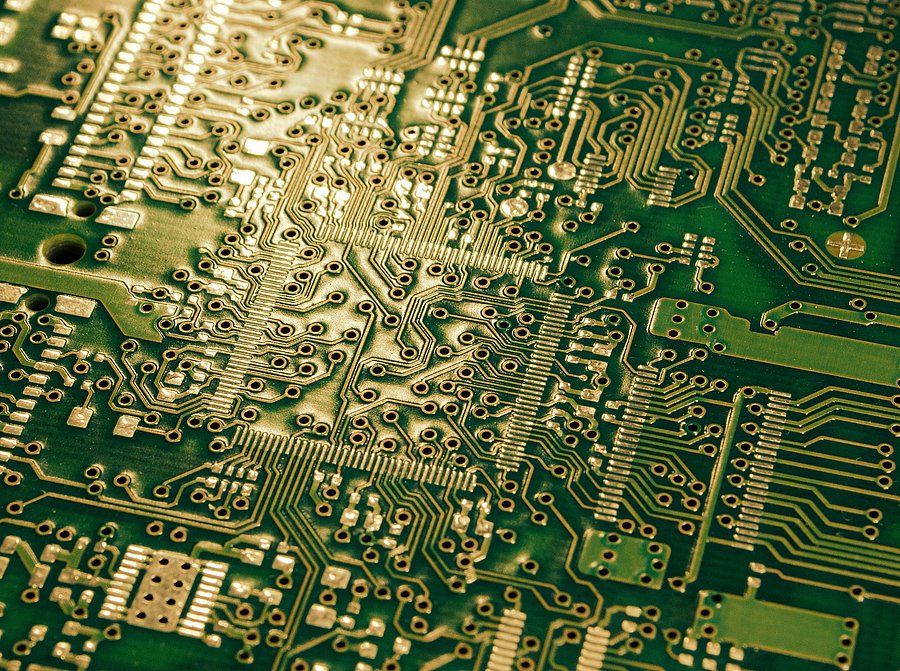

"The project marks an important step in the automation and digitalisation of production processes and offers great potential for increasing efficiency and sustainability in electronics production," says Prof. Dr.-Ing. Stefan Bracke // Photo Chair of Reliability Engineering and Risk Analysis

Printed circuit boards pass through several stages in the production process, each of which requires visual inspection in order to detect defects at an early stage. The inspection of bare PCBs after the tinning process is particularly challenging. Here, reflections at certain solder joints trigger false error messages that lead to the rejection of an actually intact PCB. A problem that could not be solved with previous testing systems.

Innovative camera concept

"There is currently no technology that can automatically inspect bare PCBs. The complex reflections of the solder joint surfaces make precise defect assessment considerably more difficult," explains project manager Prof Dr Stefan Bracke from the Chair of Reliability Technology and Risk Analysis. In cooperation with Pentagal Chemie und Maschinenbau GmbH and his research assistant Jannis Pietruschka , he wants to develop a new type of inspection concept that records different viewing angles - and is therefore less susceptible to reflections. Defects in the images are then detected using AI-based evaluation and prediction algorithms to enable generalised defect detection without reference patterns.

The quality inspection should take place directly after the tinning process, before further components are mounted on the PCBs. This saves resources and significantly reduces rejects. "The project marks an important step in the automation and digitalisation of production processes and offers great potential for increasing efficiency and sustainability in electronics production," says Stefan Bracke.

Extensive test series in prototype test system

Together with Pentagal, the software developed by the chair is being integrated into a prototype test system and tested for reliability in extensive test series. Pentagal is responsible for the design of the mechanical and mechatronic system components and plans to integrate the system as a module in its hot-air tinning systems in future.

The project is being funded by the Federal Ministry for Economic Affairs and Climate Protection (BMWK) with 216,683 euros over two years.